Most of us take part in 3D printing as a hobby to print cool designs or fundamental parts to solve a problem. However, in the past decade, 3D printing has elevated past simple designed parts and models to large-scale projects in different industries. Some companies use 3D printing to create prototypes of a product or creation. Architects do this to showcase their designs and ideas before construction begins. Other companies use 3D printing as a form of manufacturing parts or the whole of a product in its final form.

Aerospace engineering takes advantage of both uses of 3D printing. 3D Printing is a vital part of both the preliminary design and final manufacturing process of aircraft and spacecraft.

What is Aerospace Engineering?

Aerospace engineering is the study and specialization of aircraft and spacecraft. Engineers in this field design different components and systems of aircraft and spacecraft, eventually manufacturing and assembling those parts into large-scale machines that traverse air and space.

Aerospace engineering is often comprised of two main specializations: Aeronautics and Astronautics.

Aeronautical Engineering

Aeronautical engineering is the study and construction of aircraft that can fly within our atmosphere. These aircraft include planes and jets, helicopters, missiles, and more.

One of the most used skills in aeronautical engineering is aerodynamics, the study of how air interacts with different objects. Planes, jets, helicopters, and other aircraft all fly through the air. Because of this, engineers must use aerodynamics to analyze how different designs will move through the air. For example, planes often have a rounded “nose”. These nose cones are designed to ensure that air passes by the plane smoothly, providing less risk for turbulence. A plane’s turning mechanism is also designed using aerodynamics, as air plays a major part in how a plane changes direction and elevation.

While this subset of aerospace engineering specifically focuses on aircraft, aeronautical engineers also help build cars, ships, and trains. All three of these are also designed based on how they interact with air. A more aerodynamic car will be able to run at higher speeds, as there is less air pushing against it. The same goes for trains and ships as well. For this reason, aeronautical engineers play important roles when designing cars, trains, and ships, not just aircraft.

Astronautical Engineering

Astronautical engineering is the study and construction of all manmade objects sent to space. This includes the design of spacecraft like rockets and space shuttles, objects like satellites and space stations, and even rovers.

While aeronautical engineering focuses on aircraft that fly within our atmosphere, astronautical engineering focuses on objects that surpass our atmosphere and travel through space. Similarly to aeronautical engineering, aerodynamics plays a big part in astronautical engineering. Rockets and space shuttles fly through the air at incredible speeds to exit our atmosphere, meaning engineers need to design them to be efficient and strong.

Another major area of study that is vital for astronautical engineering is thermal and propulsion study. When objects exit the atmosphere, they’re exposed to massive amounts of heat. Astronautical Engineers must know how to eliminate any problems with heat affecting a spacecraft. Propulsion systems are how spacecraft and aircraft move through the air. Creating an efficient propulsion system also creates an efficient flying experience for both spacecraft and aircraft.

Prototyping

What is Prototyping?

Everything made artificially was once a prototype, a scale or not-to-scale model representing a basic non-final version of a product. For phones, laptops, cars, buildings, and almost anything else you can think of, prototyping is used to ensure accuracy and reliability before manufacturing the final product. Similarly, aircraft and spacecraft undergo heavy prototyping before the final manufacturing and assembly of parts.

The importance of prototyping when creating innovations can be modeled by the creation of a simple pen. Before mass manufacturing the pen to sell, the creators of the pen will first design and build multiple iterations of designs. These basic models are put to different tests to determine which model will be a better design for the product. After prototyping to determine the best design for the pen, it will prove to be a much better product once released to the public

Prototyping using 3D Printing

With aerospace engineering, it isn’t as simple as creating different model pens. There are far more consequences if a final project goes wrong. Years of work and millions of dollars would be going to waste by just one small problem. For this reason, engineers prioritize perfecting their designs by making prototypes of them.

Like many other areas of engineering, 3D printing has become an efficient and easy-to-use tool for many aerospace engineers to prototype a design. Using 3D printing to make small parts saves lots of time during the production of a rocket or aircraft. The bioplastic materials that standard 3D printers use offer a less expensive and environmentally friendly alternative to traditional prototyping materials.

Overall, 3D printing has and will continue to save time, money, and effort in the prototyping stage of production, one of the most essential aspects in all of engineering.

Additive Manufacturing

What is Additive Manufacturing?

We’ve always talked about 3D printing as a simple hobby us, as most of us buy standard 3D printers that can print within a limited space. Now it’s time to take a step back and understand the bigger picture around 3D printing: Additive Manufacturing.

To put it in simple terms, 3D printing falls under the category of additive manufacturing. Additive manufacturing is a form of creating objects in layers of a specific material. This differs from older methods of manufacturing that involved machines cutting into a specific material to form the desired shape. The 3D printers we use are an example of this. 3D printers extrude and place filament in hundreds of layers, to build up a certain shape.

How is it Useful in Aerospace Engineering?

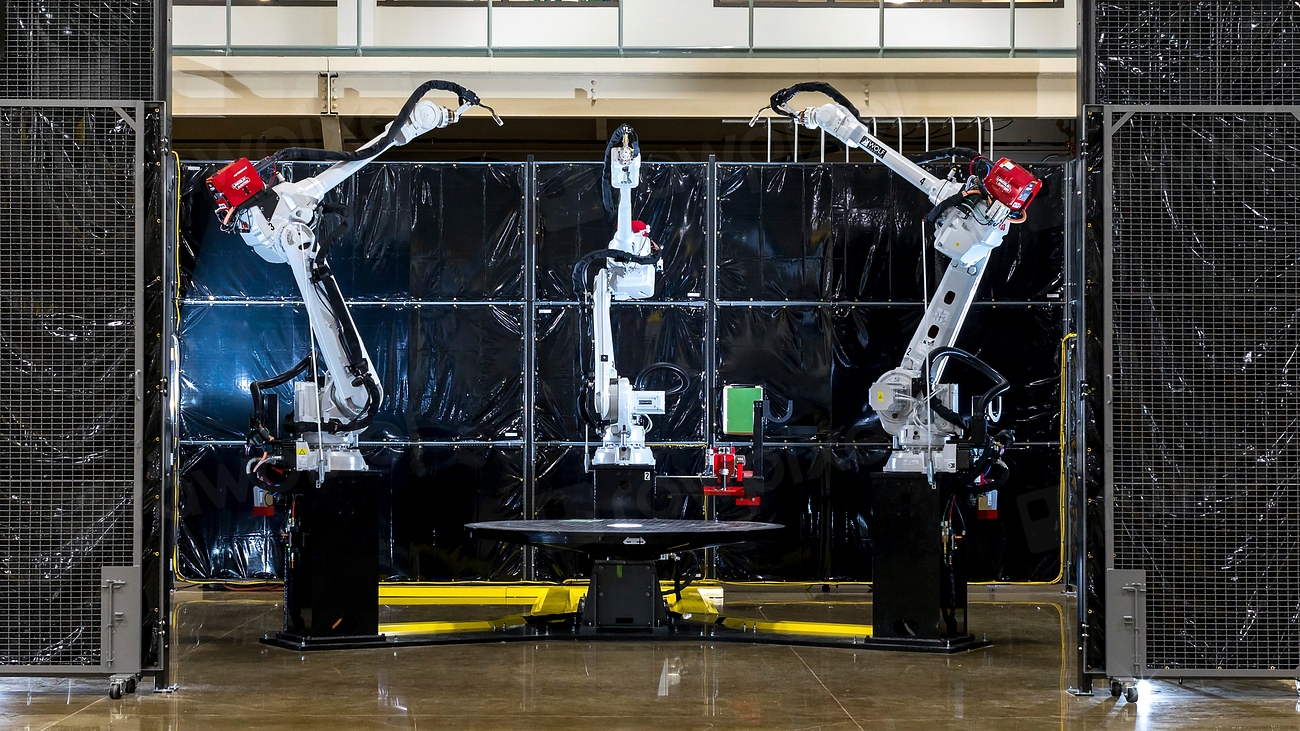

In aerospace engineering, 3D printing is most commonly used to manufacture the final components and systems of spacecraft and aircraft with high efficiency. Prototyping is still an important aspect of aerospace engineering, one that uses 3D printing as well. However, in the past decade, many new companies have created industry-scale, highly advanced “3D printers” that act in the same way regular 3D printers act. These machines make use of additive manufacturing to put together layers of metal, plastic, and other materials to construct certain parts of an aircraft or spacecraft.

Example: Rockets

Contrary to what many people believe, rockets were originally very inefficient to build. The process of constructing a rocket wasn’t automated until very recently. Before additive manufacturing, hundreds of carefully cut panels had to be manually assembled by hand. This would take lots of time, energy, money, and thousands of people to build just one rocket. To make things harder, many times rocket launches would fail, meaning a second rocket would have to be reconstructed.

In the past decade, engineers have solved this issue by applying additive manufacturing to the construction of rockets. Instead of manually putting together thousands of different components by hand, some companies have developed advanced industrial 3D printers that build rocket parts using additive manufacturing. Regular 3D printers use bioplastics like PLA and ABS filament. However, these large-scale 3D printers use metal alloys like steel and aluminum to construct strong parts.

The First 3D Printed Rocket to Reach Space

One of the most successful companies that takes advantage of additive manufacturing is Relativity Space. Relativity Space used advanced 3D printing machines to construct parts like engines and even the entire body of the rocket.

Using additive manufacturing saved Relativity Space lots of time, money, and effort on their first rocket, Terran 1, while still constructing a reliable rocket. This method, in contrast to traditional manufacturing methods, elevated Relativity Space’s success in the Aerospace Industry.

Once the Terran 1 was finished, it was considered the world’s largest 3D-printed object. On March 22, 2023, the Terran 1 was successfully launched into space, becoming the very first 3D-printed object to reach space. By mass, this rocket was 85% 3D printed, yet it was still able to surpass the barriers of our atmosphere, proving the power and effectiveness that 3D printing and additive manufacturing brings to modern engineering.

See more about Relativity Space’s launch of the first-ever 3D-printed rocket in space:

Summary

Most of us use 3D printing to create decorative and simple models, but 3D printing is also used by the most advanced aerospace engineering companies, to create spacecraft and aircraft. 3D printing can be vital in aerospace engineering for prototyping and testing different parts and systems to ensure accuracy and precision. In the last decade, 3D printing has been more commonly used to make the final physical parts and components of aircraft and spacecraft thanks to the modern advancements in additive manufacturing.

With increasing efficiency, reusability, and lower costs, 3D printing technology has skyrocketed in the aerospace engineering industry and will continue to do so for years to come.