For more than a decade, the uprising of 3D Printing and additive manufacturing has proven to be a major achievement in engineering. Most of us participate in 3D printing as a hobby or personal interest. However, 3D printing is also used by many engineers and designers to save time, money, and effort.

Many companies use 3D printing to create fast models. This process of creating models of products or projects is called Prototyping. Other companies sometimes use 3D printing techniques to manufacture a final product to sell. Today, we continue to see the effects of 3D printing in numerous industries of engineering, design, and even art. Today, we’re taking a closer look at the field of architecture, and how 3D printing is starting to play a vital role in the success of many architectural projects.

What is Architecture?

As with all fields of engineering/design, we must first understand the field of architecture. Architecture is the design of space for human interaction. This typically includes homes, apartment buildings, bridges, shops, and any other form of structure. Architects work on both the interior and exterior of spaces. For example, an architect would design the exterior shape of a house, as well as the placement of rooms from the inside.

Skills

Architecture requires skills similar to many other fields of design. An architect must be knowledgeable in geometry, 3D composition, and 3D design to design spaces that use space most efficiently. Architects use CAD to design the interior and exterior of buildings and other structures.

Every human-built space in the world was designed by an architect. Every home and building went through different phases of design before being constructed. Your own home is a product of comprehensive design from an architect. Every doorway, room placement/location, window, closet, and overall structure and shape of your home, both on the interior and exterior, was carefully designed using architectural methods.

Architects must also understand the nature of human movement. For every building, each element of the building is placed in a specific position and location that appeals to the people inside the building most efficiently. For example, placing the front door right in front of a staircase is never a good idea (as shown by the picture below). Architects must decide how to place elements of a home or building so that the inhabitants can move around the space most efficiently.

Part of architecture is deciding which materials to use for different elements of a project. Architects must determine which materials appeal most to their needs of cost, stability, durability, color, and more. For example, using glass as the main material for the walls of a building is not a good idea. The entire building would tumble instantly. An architect must ask and answer the question, “What material will make these walls strong, while also not being too expensive?”

Prototyping

Every field of engineering, design, and even art goes through a stage called prototyping. Prototyping is the process of creating multiple simple drafts of a project to analyze the effectiveness and flaws of a design. Manufacturing and distributing a product straight from the design, without prototyping, could lead to many errors that weren’t taken into account while designing. Creating prototypes ensures fewer errors and greater effectiveness of a product.

If you’re sitting on a chair right now, that chair went through numerous stages of design and manufacturing. Each design draft that your chair went through was a different prototype of the chair. Eventually, the engineers found a prototype that worked most effectively and released that design as their final product, the chair you’re sitting on right now.

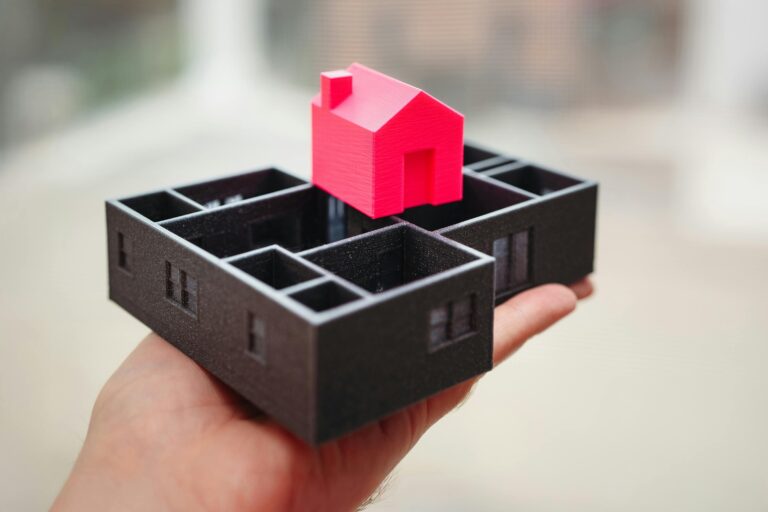

Similarly, architects always use prototypes before finalizing their designs. These prototypes of often small-scale models of structures or spaces. Creating multiple real-life buildings as prototypes is very inefficient and costly. Buildings take lots of time to construct, so small-scale models are useful for quick prototyping, saving architects lots of time, money, and of course, tears.

Prototypes aren’t only convenient for architects. Small-scale models also help the public and clients visualize how buildings and other structures will look after construction. Before beginning construction, clients want to understand how their structure will look. Technical drawings are great for architects, but 3D models work better for non-architects to visualize how the final product will look.

Why Use 3D Printing?

3D Printing is a common way that these models are created. When architects finalize a design in CAD, they sometimes use 3D printing to create small-scale models of their design. These models help visualize how effective their design is while showcasing their design to the public before construction begins. These models act as 3D “blueprints” for their design.

Traditionally, architectural models are made from wood and other materials by carefully cutting them by hand or with machinery. One common practice was to assemble hundreds and thousands of cards in particular shapes to construct a small-scale model. Assembling prototypes by hand takes lots of time and effort.

3D Printing offers a more automated, quicker, cheaper, and more accurate process to create models of architectural structures, in comparison with traditional model-making methods. A model building that would take days of work to construct by hand could be completed in less than 12 hours using 3D printing.

Not only are these models faster to create, but they are also more accurate. Hundreds of square cards can only take you so far in terms of accuracy. 3D printing creates a model straight from the original CAD design, basically copying every millimeter of the model.

Summary

Overall, 3D printing in architecture helps many companies save time, money, and effort during the prototyping stages of design. Prototypes can now be made much easier using 3D Printed models, rather than spending time carving wood and using cards to create the shape of a building. 3D Printing is also an automated process, increasing the accuracy of models and lowering the chances of error. With this technology, architecture companies around the world can complete projects faster and more efficiently.