Nike Vaporfly Flyprint Running Shoes

Any runner would look at the words 3D Printed Supershoes and think, “How?” How could a 3D Printer create running shoes? How do the shoes not break down? 3D-printed running shoes seem impossible, yet they exist.

Most runners know of the renowned Nike Vaporfly supershoes. These shoes are used for racing by many, from high school athletes to elite marathoners. However, few are aware of a 3D-printed version that Nike produced exclusively for marathon runner Eliud Kipchoge.

At the time, Kipchoge raced with Nike Vaporflys, but had complaints about the shoe in wetter settings. The problem was that the shoe absorbed water, making it heavier. To tackle this problem, Nike started working on a new design for the upper of the shoe. The finished design, called Nike Flyprint, used 3D printing technology to create a textile that prevents the absorption of water.

Once completed, Kipchoge used this shoe in the 2018 London Marathon, which he won by 32 seconds. Currently, Nike’s Flyprint technology is not available to the public for purchase and is still undergoing improvements. In the past few months, Nike has received approval for a new patent relating to 3D printing technology, meaning we may see a new and improved version of the Flyprint upper in the future.

Terran 1 3D Printed Rocket

Believe it or not, this is real. In March of 2023, an aerospace company known as Relativity Space launched the world’s first 3D-printed rocket into space. The rocket was called Terran 1, and was unsurprisingly the largest 3D printed object to date.

Traditionally, rockets are constructed by assembling thousands of parts using manual labor. This would often take many months and even years to construct a rocket. After testing, if something goes wrong, many more months would be spent reconstructing and retesting the rocket.

Additive Manufacturing technology now eliminates this immense time commitment. With specialized 3D printers, Relativity Space was able to construct the entire rocket’s frame using only 3D printing, saving time, effort, and even costs. By the end of construction, the Terran 1 was 85% 3D-printed by mass and was capable of escaping the boundaries of our atmosphere.

While the rocket was mostly 3D printed, it wasn’t made using regular 3D printers that most hobbyists use. The rocket frame and other parts were manufactured by a special machine that used additive manufacturing technology. While none of us at home could create such an object using only a 3D printer, the success of Terran 1 opens up countless possibilities for the future of additive manufacturing, 3D printing, and aerospace engineering.

Currently, Relativity Space is working on an improved version of the Terran 1, called Terran R. Learn more about Relativity Space’s Terran 1:

Prosthetic Limbs

Prosthetic limbs are among the most significant innovations in the medical field, providing support and stability for individuals who have lost limbs. Since the first prosthetic, dating back to ancient Egypt, technology for prosthetic limbs has continued to advance.

Over the past few decades, computer-aided design has helped biomedical engineers design advanced prosthetic systems to feel more like real limbs. Most of the time, modern prosthetics are manufactured using injection molding or vacuum forming.

Injection molding involves injecting liquid plastic into handmade molds based on the patient’s limb shape. Vacuum forming involves heating a plastic sheet, then bending it to match the shape of a handmade mold. These traditional casting methods usually take a lot of time to create a prosthetic.

Because of this, some experts have turned to 3D scanning and 3D printing. First, a patient’s limb is digitally scanned and made into a 3D computer design. Then, a socket is designed using the scanned limb. The socket is then printed using extremely accurate 3D printing and special materials.

Additive manufacturing opens up countless possibilities for the creation of prosthetic limbs, including more efficient manufacturing methods and better/cheaper materials. Many companies, like Formlabs, continue to study and produce prostheses using 3D printing manufacturing methods.

Cars and Car Parts

Similarly to the 3D printed rocket, this is real. Also, similarly to the 3D printed rocket, “Cars and Car Parts” refer to real-life-sized cars, not scaled-down models.

The manufacturing of cars is a very long process. Most automobile companies manufacture different components of their car, while also outsourcing some components from other companies. These components are then assembled, commonly in an assembly line, to create the finished automobile.

For many of these components, companies have turned to additive manufacturing methods of production. Like many other products in this list, the creation of these parts requires high-level level precise 3D printers and metal filament. Additive manufacturing heavily reduces the amount of metal waste and the time spent on manufacturing, saving time and costs.

Of course, a fully 3D-printed car can’t simply be created on a common hobby-level 3D printer. Projects like these require the most state-of-the-art additive technology. However, printing car parts and even full cars has been done on a few occasions. One example is when Dr. Sterling Backus and his son 3D printed an entire drivable Lamborghini Aventador! The project started in early 2018, but Dr. Backus and his son continue to add to the car to this day.

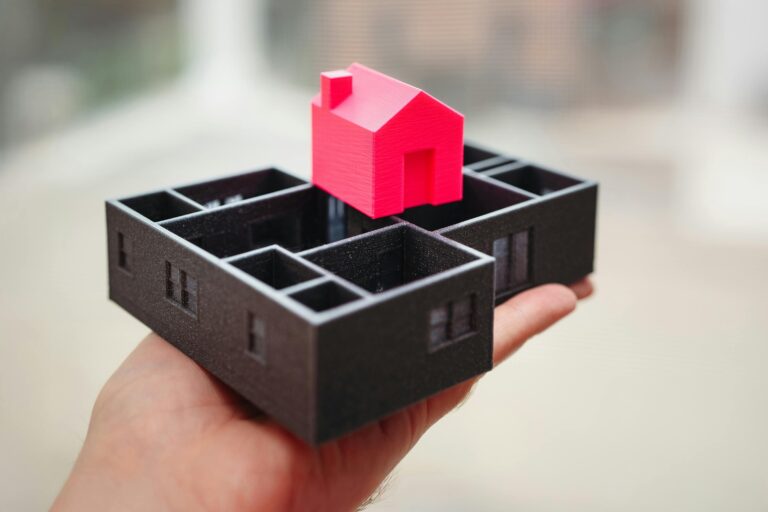

Homes

By this point, we know of 3D printed cars, prostheses, and even entire rockets. But who would’ve thought that entire livable homes are being constructed using 3D printing technology?

Like other unbelievable 3D printed projects on this list, the printing of homes can’t be done with the typical everyday hobby-level 3D printer. The machine used to create homes like this is very different from regular 3D printers. Instead of releasing filament from a nozzle, this giant machine releases large amounts of cement to construct the walls of a house from the ground up.

Although this machine looks like nothing most people have ever seen, it functions like a very large 3D printer. The cement extruding from a large nozzle is similar to standard filament extruding from the nozzle of an FDM printer. The machine also builds up concrete from the ground up, layer by layer, just like a regular 3D printer.

This process of constructing homes using additive technology has many benefits, including faster production, less required labor, and overall lower costs. However, many people are concerned about the drawbacks. Some are worried that the spread of this construction method could leave many construction workers unemployed. Others worry that prices of homes may stay the same, even if production costs decrease.

Regardless of the potential drawbacks, it’s very impressive to see how far additive manufacturing has come. It’s hard to deny that if it’s used for the correct purposes, and if it benefits the correct people, 3D printing technology provides a promising future for the construction of homes all over the world.